This is a guide to understanding the differences between cleaning, sanitizing, and disinfecting. It is focused on produce farms and is motivated by current concerns over the COVID-19 pandemic.

By Chris Callahan, UVM Extension with review and input from team members of the Produce Safety Alliance (Cornell University), Hans Estrin (UVM Extension), Lisa McKeag (UMass Extension), Phil Tocco (Michigan State University), and Annalisa Hultberg (University of Minnesota).

This guide is intended to provide information about the differences between cleaning, sanitizing and disinfecting hard surfaces on produce farms. The motivation for this guide is the current COVID-19 pandemic and questions from growers about what can be used and how much should be used. It is important to note that COVID-19 has not been found to be transmitted via food and that this guide is not supporting the disinfection or sanitization of produce. Also remember that cleaning should be a first step in any of these activities. Follow the EPA label for your product and always wear personal protective equipment as indicated.

Also available as a PDF.

What is the difference between cleaning, sanitizing, and disinfection?

The CDC provides more detail on their cleaning website, but the take-homes are:

- “Cleaning removes germs, dirt, and impurities from surfaces and objects…using soap (or detergent) and water to physically remove [them].”

- “Sanitizing lowers the number of germs on surfaces or objects to a safe level, as judged by public health standards or requirements.”

- “Disinfecting kills germs on surfaces or objects. Disinfecting works by using chemicals to kill germs on surfaces or objects. This process does not necessarily clean dirty surfaces or remove germs, but by killing germs on a surface after cleaning, it can further lower the risk of spreading infection.”

When should I sanitize and when should I disinfect?

- If you have a possible hazard (e.g. pathogenic E. coli in growing environment) cleaning and sanitizing is appropriate for food contact surfaces such as harvest bins, wash line food contact surfaces, and sorting and packing tables. This is doing what you would normally do within a farm food safety plan or cleaning and sanitizing SOP. Each farm and situation is unique, but some examples of when you might choose to sanitize include:

- Sorting table in an open wash/pack shed

- CSA bins returning from community distribution with no known illnesses

- Farm stand counters

- If you have a known or probable (likely) hazard (e.g. visible feces, bodily fluids, or blood or an employee is found to be ill with communicable disease) cleaning and disinfecting is appropriate. This is generally an activity focused on specific surfaces that uses a higher concentration of disinfecting chemical and/or longer contact times, when compared to sanitizing. These surfaces may be high touch areas that many people touch regularly or they may be surfaces with visible contamination. Each farm and situation is unique, but some examples of when you might choose to disinfect:

- Visible feces, blood, or other bodily fluid on food contact surfaces

- CSA bin returned from a household with a known transmittable illness

- CSA bins returned from a high volume distribution in a location with high probability of known illness

- Tractor / truck cab after operator has been diagnosed with a known transmittable illness

- Credit / debit card machine key pads

Can I use a sanitizer or disinfectant not labeled for coronavirus for protecting against coronavirus?

Unfortunately, nothing is currently labeled for killing SARS-CoV-2, the novel coronavirus we’re dealing with. The virus is too new to have had anything be tested for efficacy. Even though many commonly-used sanitizers are labeled for sanitizing and disinfecting food contact surfaces, the labels will not list SARS-CoV-2 as a target organism. Use of the product may be appropriate to the label when the target is more generally pathogenic microorganisms such as in routine sanitation. Routine sanitation practices are expected to also control SARS-CoV-2 levels.

Some products are labeled for other coronavirus or viruses that are more difficult to kill, however. The EPA does provide “List N” which are disinfectants that they approve for use against SARS-CoV-2. For example, both Ultra Clorox Brand Regular Bleach (EPA#5813-103) and CloroxPro Clorox Germicidal Bleach are included in this list (EPA#67619-32). This list includes products with the same active ingredients as some sanitizer products used on the farm. For example, there are PAA/Hydrogen Peroxide solutions on this list which use the same active ingredients as the Sanidate, Tsunami, and Vigorox branded products which are common on many fruit and vegetable farms. It stands to reason that these other products would also be effective when used accordingly (at the right dose, in the right application, with the right amount of time, etc.) These are not normal times, and sourcing products that are on List N may not be possible. If you have a sanitizer with common active ingredients, it may be your best choice.

How do I adjust my use of a sanitizer for disinfection?

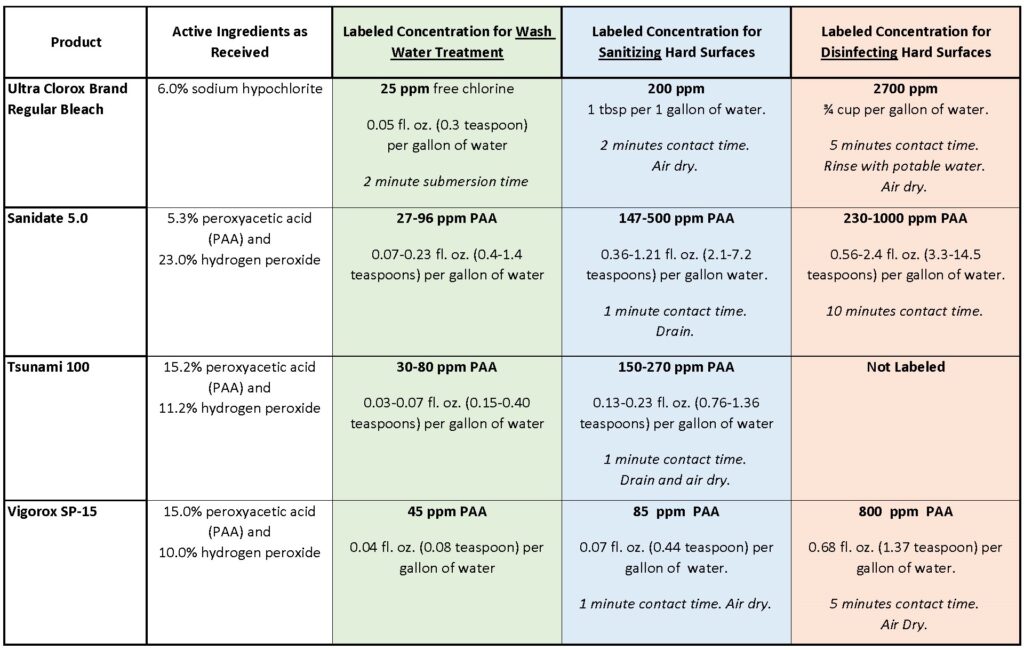

- Clorox Bleach Example: Reviewing the label for Ultra Clorox(R) Brand Regular Bleach (alternate name, “Clorox Germicidal Bleach”), a 6.0% sodium hypochlorite product, we note that this product is labeled as effective against human coronavirus (p.35 revised). We also note that the concentration used for disinfection of hard, nonporous surfaces (p. 14 and 22 of PDF) is 2700 ppm (¾ cup per gallon of water) available chlorine, a contact time of 5 minutes is required and a rinse with potable water and air drying are required. This is a higher concentration and longer contact time compared to the lower rate used for sanitizing (p. 14 of PDF) of 200 ppm (1 tbsp per 1 gallon of water) with 2 minutes of contact time followed by air drying. For treatment of water use for fruit and vegetable washing (p.37, “For Fruit and Vegetable Washing”) the concentration is 25 ppm with a submersion time of 2 minutes. The effectiveness of chlorine depends on the pH of water.

- Sanidate Example: Reviewing the label for Sanidate 5.0 (p.12, “General Disinfection”), a 5.3% peroxyacetic acid and 23.0% hydrogen peroxide product, we note that the concentration used for disinfection is 0.5-2.2 fl. oz. per gallon of water (230-1000 ppm of peroxyacetic acid in water) with a contact time of 10 minutes compared to the lower rate used for sanitizing (p.10, “Sanitization of Food Contact Surfaces”) of 1.6-5.4 fl. oz. to 5 gallons water (147-500 ppm) with a 1 minute contact time and draining afterward. Later in the label, we find the postharvest water application to control cross contamination that we’re most familiar with (p. 20, “Treatment of Fruit and Vegetable Processing Waters”) where the rate of use is 59.1-209.5 fl. oz. per 1000 gallons of water (27-96 ppm). Biosafe, the manufacturer of Sanidate, also provides more specific and narrow PPM ranges for wash water treatment when handling specific crops.

- Tsunami Example: Reviewing the label for Tsunami 100, a 15.2% peroxyacetic acid and 11.2% hydrogen peroxide product, we note that there is no labeled use as a disinfectant. The label guidance for sanitization (p.4, “Sanitizing Food Contact Surfaces”) is 1.0 to 1.8 fl. oz. per 8 gallons water (1000-1800 ppm of product, 150-270 ppm of PAA) with a contact time of 1 minute with draining and air drying afterward. We also note that the postharvest water application to control cross contamination that we’re most familiar with (p. 2, “For Pathogen Reduction and Control in Fruit and Vegatable Processing Waters in Food Facilities”) has a rate of use of 2.5 to 6.7 fl. oz. per 100 gallons of water (30-80 ppm PAA).

- Vigorox Example: Reviewing the label for Vigorox SP-15 (p.5 “Surface Disinfection”), a 15.0% peroxyacetic acid and 10.0% hydrogen peroxide product, we note that the concentration used for disinfection is 0.5-2.2 fl. oz. per gallon of water (230-1000 ppm of peroxyacetic acid in water) with a contact time of 5 minutes with air drying compared to the lower rate used for sanitizing (p.4, “Sanitization of Non-Porous Food Contact Surfaces”) of 3.1 fl. oz. to 50 gallons water (85 ppm PAA) with a contact time of 1 minute with air drying. The postharvest water application to control cross contamination that we’re most familiar with (p.6, “For Reducing Pathogenic Foodborne Bacteria in Processing Waters for Fruits and Vegetables”) where the rate of use is 0.54 fl. oz. per 16 gallons of water (45 ppm PAA).

For help determining appropriate mixing rates for volumes other than those above, see the sanitizer dose calculator available online. For guidance about safely dispensing sanitizers, see our guide.

There’s a Range Listed on the Label! How Much Should I Use?

The amount of sanitizer you use depends on the intended purpose.

Example: Sanidate 5.0 is intended to be used at a concentration of 27-96 ppm according to the label when used for postharvest wash water treatment. This means a “dose” of 0.06-0.20 fl. oz. of Sanidate 5.0 per gallon of wash water. For leafy greens, Biosafe, the manufacturer of Sanidate, recommends 40-60 ppm which means 0.10-0.14 fl. oz (roughly 1/2 to 1.0 teaspoons) per gallon of water. Dosing at the high end of this range will provide extra sanitizer which is helpful since it gets used up during the wash cycle. You should confirm the concentration of sanitizer at the start and end of the wash cycle using test strips. Our online dose calculator may be helpful.

Stay safe! This video walks you through how to handle sanitizer safely

Share this post:

http://go.uvm.edu/clean-sanitize-disinfect

Acknowledgements

This resource was developed as part of the Food Safety Outreach Program under grant number 2020-70020-33003 from the USDA National Institute of Food and Agriculture and also funded, in part, by the USDA Northeast Sustainable Agriculture Research and Education program through award LNE19-375 and by the Food and Drug Administration through The Vermont Agency of Agriculture Food and Markets via the Integrated Extension Educational Programming in Support of the VAAFM Produce Program Grant 02200-FSMA-2018-01. The views expressed in the publication do not necessarily reflect the official policies of the U.S. Department of Agriculture, the U.S. Department of Health and Human Services or the Vermont Agency of Agriculture; nor does any mention of trade names, commercial practices, or organization imply endorsement by the United States Government or the State of Vermont. It is offered without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, disability, protected veteran status, or any other category legally protected by federal or state law. This project was supported by the Food and Drug Administration (FDA) of the U.S. Department of Health and Human Services (HHS) as part of a financial assistance award 02200-FSMA-24-01 totaling $30,000 with 100 percent funded by FDA/HHS. The contents are those of the author(s) and do not necessarily represent the official views of, nor an endorsement, by FDA/HHS, or the U.S. Government.