Would you rather listen to this blog post? You can listen and learn about these spray table options via this episode of The Ag Engineering Podcast.

Spray tables are commonly used to rinse bunched produce or crops with relatively high soil load. They are typically made from a porous horizontal material supported by a framed structure. A very common approach is to use 2×4 lumber for framing and either hardware cloth or welded wire fencing stapled to the top. Although this approach is inexpensive and uses readily available materials this design has two main downsides:

- Wood and galvanized metal are not very easy to clean completely.

- Wood and galvanized metal will wear over time with repeated soaking and drying cycles.

If we apply the principles of hygienic design to a spray table it becomes clear that we should think about the cleanability of the materials and their assembly while also thinking about how the materials will hold up over time.

Below are some options for spray table materials and approaches that should help make yours easier to clean and more durable. These options are sorted by lowest per square foot cost to highest. Support structure and legs were not accounted for in the cost.

Support Structures

Depending on the material chosen for the main surface of the table, different support structure approaches will be needed to considered. Some of the materials are rigid and will need very little support in mid-span, while others are more flexible and will need more support. The support can be made as a wooden or metal frame. Some supports don’t need to be built. If the spray surface is rigid enough you can span the rigid material across cinder blocks, sawhorses, crates, on top of dunk or stock tanks, or even between two other table surfaces.

Spray Surfaces

Spray surface materials should be porous or open mesh to allow water and soil to pass, but have tight enough mesh to support produce being cleaned. Material used for spray surfaces should be easy to clean, durable, and compatible with cleaners and sanitizers. Spray surfaces vary in their rigidity and, therefore, will require varied approaches to support. Below are several options that range in cost from $0.13 to $30 per square foot.

Plastic Snow Fence

Plastic snow fence is similar to the safety fence but has a slightly larger opening (typically 1-1/2″x1-3/4″) and might be challenging for some crops. This material is very inexpensive and readily available (in snowy states that is!)

Pros: Inexpensive. Easy to cut.

Cons: Larger openings than safety fence. Less durable than steel options. Requires more support of spans.

Cost: $0.13 per square foot

Plastic Safety Fence

Similar to snow fence, plastic safety fencing avoids rusty wire as a food contact surface. This material has a typical mesh size of 1-1/4″x1-1/2″.

Pros: Inexpensive. Easy to cut.

Cons: Less durable than steel options. Requires more support of spans

Cost: $0.23 per square foot

DIY PVC Wash Table

Here is another DIY approach using PVC pipes instead of wood for a spray table frame and green PVC coated welded wire (2″x3″ mesh) for the spray surface. This approach is described in this guide available from Cornell.

Pros: Lightweight. Custom size, easy to assemble.

Cons: Challenging to clean (requires complete disassembly and/or cleaning in between the different components

Cost: $0.37 per square foot for spray surface

“Dura-Slat” Hog/poultry flooring

The holes in Dura-Slat flooring have 1.1″ holes. Available in white, but this color does not have the UV resistance that the black color option has.

Pros: Easy to see (to confirm cleanliness.) Rigid material requires less mid-span support.

Cons: White not UV resistant.

Cost: $2.29 per square foot

Wire Closet Shelving

Wire close shelving is commonly available at hardware and big box stores. The plastic-coated wire shelving is more sturdy than a fence or mesh material and does not need a frame to support spans.

Pros: Commonly available. Rigid material.

Cons: Still needs legs or support structure. Can be a shallow workspace. Coating may flake over time.

Cost: $2.40 per square foot.

“Dura-Bench” Greenhouse Benches

Greenhouse benches, such as Dura-Bench, are an off the shelf option. They can be ordered with legs ready to install and this is a durable multi-use piece of equipment.

Pros: UV Resistant. Rigid. Legs are available.

Cons: More expensive option.

Cost: $2.73 per square foot

Crates or Trays

One of the simplest options for a spray table may be something you already have on your farm. Using milk crates, bulb crates or other vented trays will provide a surface that lets water and soil drain away from the vegetables. Bread trays (22″x26″ or 26″x29″) or flatware trays (19.75″x19.75″) provide a larger, shallow work area. One option is to place 3-4 clean crates upside down next to each other to create a larger table.

Pros: No additional expense. Already on-farm.

Cons: Smaller work area, but could be suitable for small volume

Cost: $2.86 per square foot

Wire Rack Shelving

Wire racks are popular among farms and food producers due to their durability, adjustable spacing, and price point. They may be epoxy coated, chrome-plated, and in stainless steel. There are several brands and a wide range of quality. Considering the varied uses on the farm, a higher end shelving unit may be worth the investment.

Chrome

Pros: Budget-friendly. Multi-use. Modular and scalable.

Cons: Coatings may flake over time leading to rust.

Cost: $2.33 per square foot

Stainless Steel

Pros: Will not rust or flake. Multi-use. Modular and scalable.

Cons: Much more expensive than coated options

Cost: $11.20 per square foot

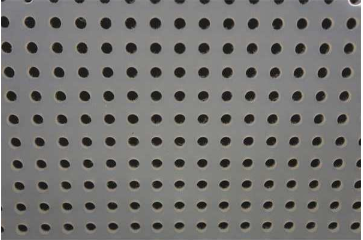

Perforated Plastic

Perforated plastic is lighter weight than perforated metal and cheaper. Look and size is like a pegboard material.

Pros: Less expensive than perforated metal options

Cons: Will need some framing and support mid-span.

Cost: $6.60 per square foot

Plastic Coated Hardware Cloth (Garden Fence)

Garden fencing or PVC coated hardware cloth is an easy to use the material. This material is readily available at local hardware stores, commonly in green though other colors are available.

Pros: Easy to find locally. Durable.

Cons: Will require some framing and support mid-span.

Cost: $6.76 per square foot

Tenderfoot Flooring

Tenderfoot is an animal-friendly flooring product which is a higher end, extremely durable expanded metal product, coated in plastic. Orange in color is bright and easy to see making it easier to confirm cleanliness.

Pros: Bright and easy to see. Durable.

Cons: More expensive than other options.

Cost: $8.61 per square foot.

Here is a video example Tenderfoot in use as a cleaning and sorting table at Wise Earth Farm.

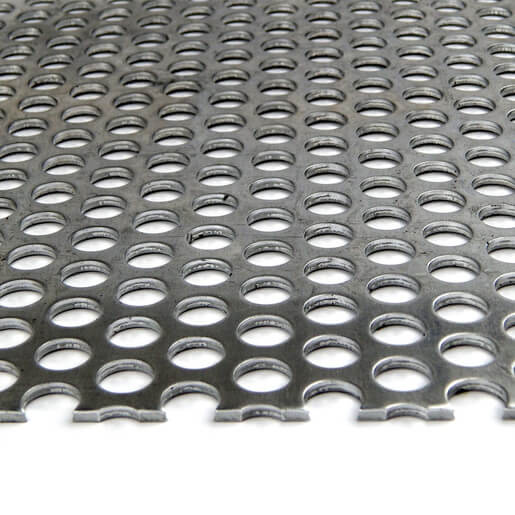

Perforated Metal

Perforated metal is available in different thicknesses and has some advantages over an expanded mental option. It is a smooth surface that reduces the risk of damage to products. This material has slightly more surface area but is smooth and easy to clean.

Pros: Easily cleanable. Extremely durable. Self-supporting and does not need mid-span support.

Cons: Heavy. More expensive option.

Cost: $16.38 per square foot

Perforated Belt

Perforated conveyor belting is another material option. This material has holes (typically 3/8″) which will let water and debris drain off easier.

Pros: Easy to clean.

Cons: Needs support. More expensive option.

Cost: $18.75 per square foot

Drying Belt

A mesh conveyor belt (referred to as a “dewatering” or “drying” belt) is used on large wash or sorting lines set-up with an air knife or a vacuum system to remove water. This mesh belt could work for a simple spay table as well. It is a tight mesh (0.09″x0.09″) and will hold some water or soil but will self drain.

Pros: Tight mesh is good for smaller crops. Easy to see to confirm cleanliness.

Cons: May hold some water. Will need some support bracing.

Cost: $27.50 per square foot

Expanded Metal Screen

Expanded metal screen is available in various materials including stainless steel, sizes and styles including coating options. It is going to be durable and has a small mesh size available. Expanded metal screen has lots of open area that allows water and soil to pass easily.

This edges of this product can be sharp which can damage produce and hold plant matter and rootlets making it more difficult to clean. Look for “rolled” or “smooth” options.

Pros: Open area. Available in stainless steel and coated options.

Cons: Expensive option. Can have sharp edges.

Cost: $28.91 per square foot

Acknowledgements

This resource was developed as part of the Food Safety Outreach Program under grant number 2020-70020-33003 from the USDA National Institute of Food and Agriculture and also funded, in part, by the USDA Northeast Sustainable Agriculture Research and Education program through award LNE19-375 and by the Food and Drug Administration through The Vermont Agency of Agriculture Food and Markets via the Integrated Extension Educational Programming in Support of the VAAFM Produce Program Grant 02200-FSMA-2018-01. The views expressed in the publication do not necessarily reflect the official policies of the U.S. Department of Agriculture, the U.S. Department of Health and Human Services or the Vermont Agency of Agriculture; nor does any mention of trade names, commercial practices, or organization imply endorsement by the United States Government or the State of Vermont. It is offered without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, disability, protected veteran status, or any other category legally protected by federal or state law.