Elizabeth Keen and her husband Al have been farming at Indian Line Farm in Great Barrington, MA for over 25 years. After taking a sabbatical in 2016, they had the realization that after 10-15 years “just running the farm” it was time that some things needed to change to make the farm more sustainable in their next phase of life. The upgrades to the farm included the purchase of a delivery van, a 30’x96’ hoop house, and replacing the 6-wire high tensile electric fence with an 8’ fence to keep the deer out. Additionally, Elizabeth decided it was time to make some improvements to the post-harvest area on the farm.

Background Info

- Markets: 250 member CSA, Farmers Market (Great Barrington, MA) local wholesale to stores and restaurants

- Growing area: 5 acres

- Total Farm: 20 Acres

- Project Cost: approx. $260,000

- Wash Pack Equipment: Greens spinner, dunk tanks, spray tables, sorting table

Barn Improvements

Making improvements to the barn was a daunting decision, but one that kept coming up as a need to address a bottleneck in its previous state. After pricing out a new building, and not feeling completely satisfied with how the new building would fit into the flow of their farm they decided to renovate the existing, old dairy barn instead.

This barn is built into a bank and the bottom floor was the primary space used for washing, packing and CSA pick up. It did include concrete floors, though rough, and featured large gutters from previous dairy operations. The two main issues were that it was dark and the ceilings were low. These were issues that started to seem surmountable after a few discussions with engineers and builders.

One of the largest things that was done was raising the floor of the barn (ceiling of the basement) so people wouldn’t hit their heads. This involved cleaning out the top of the barn and installing new laminated veneer lumber (LVL) beams, support posts, floor joists and decking. By doing so, they were able to engineer the floor to only need 3 support posts instead of 4 reducing the cramped feeling.

The concrete floor below was significantly upgraded when they filled in the existing the gutters and poured a new, smooth, concrete floor.

Goals of the farm

Elizabeth and Al have 4 goals at Indian Line Farm that keeps them focused on the long game:

1. Bring the land to bear

2. Laugh

3. Pay off the debt

4. Eat Responsibly

Wash/pack equipment

Barn Layout & Flow

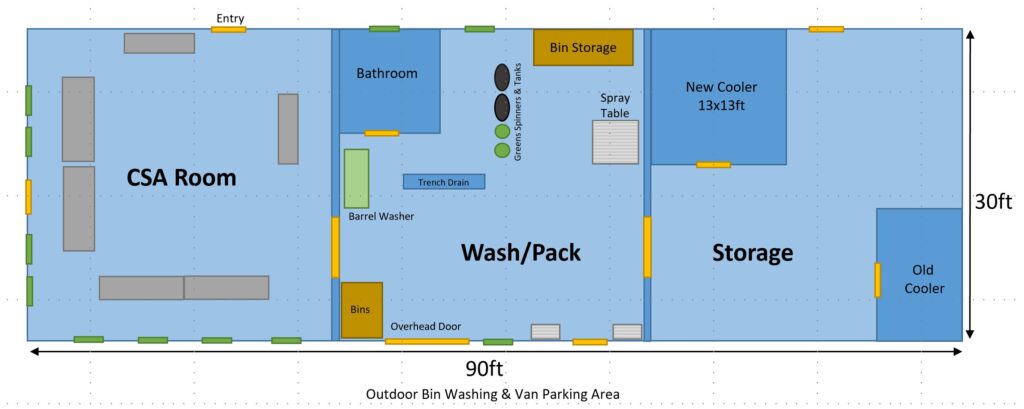

The bottom of the barn is split into thirds; a CSA room, a wash/pack space featuring a bathroom in the corner, and a cooler/storage area. Each section is Approximately 30x30ft with an 8’ ceiling.

Special Features

A few design features that makes this barn unique and convenient for vegetable washing and packing:

- Wide door into the 13×13’ cooler to accommodate a pallet jack

- Hannay hose reels for storing hoses overhead but keeping them convenient for use

- Stands for dunk tanks purchased from Uline

- Barrel washer has a home inside the building

- Centrally located drain

- Electric heat pump to heat the space, powered by on-farm solar panels.

Cost

The Cost of the renovation was approximately $260,000 which covers everything but the shell of the barn that they started with. This includes demolition, pouring a new floor, building a new ceiling, insulation, electrical, adding water lines, installing a new septic line, bathroom, heat pump, and a cooler.

This project was made possible thanks to a $219,000 in grant funding from the Massachusetts Department of Agricultural Resources.

Favorite things

When asking Elizabeth about her favorite things in the space she noted the benefit of “being able to roll things, and the ease of movement of materials, bins on dollies vs. carrying one bin at a time.” Lighting was another area of improvement – “we were literally working in the dark”. Because you can see the nooks and crannies, she now reflects that “this is what a clean space feels like.” And having heat in the space? “…[it] has been stellar”

Lessons Learned

There are only a few things that Elizabeth wishes she had done differently so far. One of them is the waterline from the well was installed undersized (3/4”) and she wishes that came into the barn in a larger line to fill tanks with a little more speed.

Secondly, they forgot to insulate under the cooler. Though not a big deal, something that got overlooked, and could have been done with this level of total renovation. It should be noted, though, that some growers find benefit from an uninsulated floor for winter storage crops because the moderate heat from the ground helps prevent freezing on the coldest nights.

The last thing she noted was that “doing this major renovation during the middle of the growing season was a real drag.” The timing of the project made wash/pack, and CSA pick-up challenging working out of and under tents was less than ideal with water drainage challenges and trip hazards all around.

Overall, Elizabeth is really happy with the post-harvest improvements that has made the day-to-day tasks on the farm much better for her and the crew. One piece of advice to those considering a project like this? “Build bigger than you think you need.”

Educational Resources Elizabeth Used

Post-harvest planning 8-part webinar

A web consult with the produce safety team helped to brainstorm construction and product flow ideas.

Farm Visit Video

Share this post

View More Post Harvest Case Studies

Acknowledgments

This case study is possible because of the hard work, wisdom, and generosity of Elizabeth and Al Keen at Indian Line Farm. Without their willingness to take the project on to begin with, deal with all the challenges that such projects bring, and complete it we would have nothing to share. We are grateful to them for their willingness to share their story and knowledge in this form so that others can learn.

Funding for this publication was made possible, in part, by the USDA Northeast Sustainable Agriculture Research and Education program through award LNE19-375, the Food and Drug Administration through The Vermont Agency of Agriculture Food and Markets via the Integrated Extension Educational Programming in Support of the VAAFM Produce Program Grant 02200-FSMA-2018-01. The views expressed in the publication do not necessarily reflect the official policies of the U.S. Department of Health and Human Services or the Vermont Agency of Agriculture; nor does any mention of trade names, commercial practices, or organization imply endorsement by the United States Government or the State of Vermont.